Plans available now! Watch the unveiling here, and the build videos here and here.

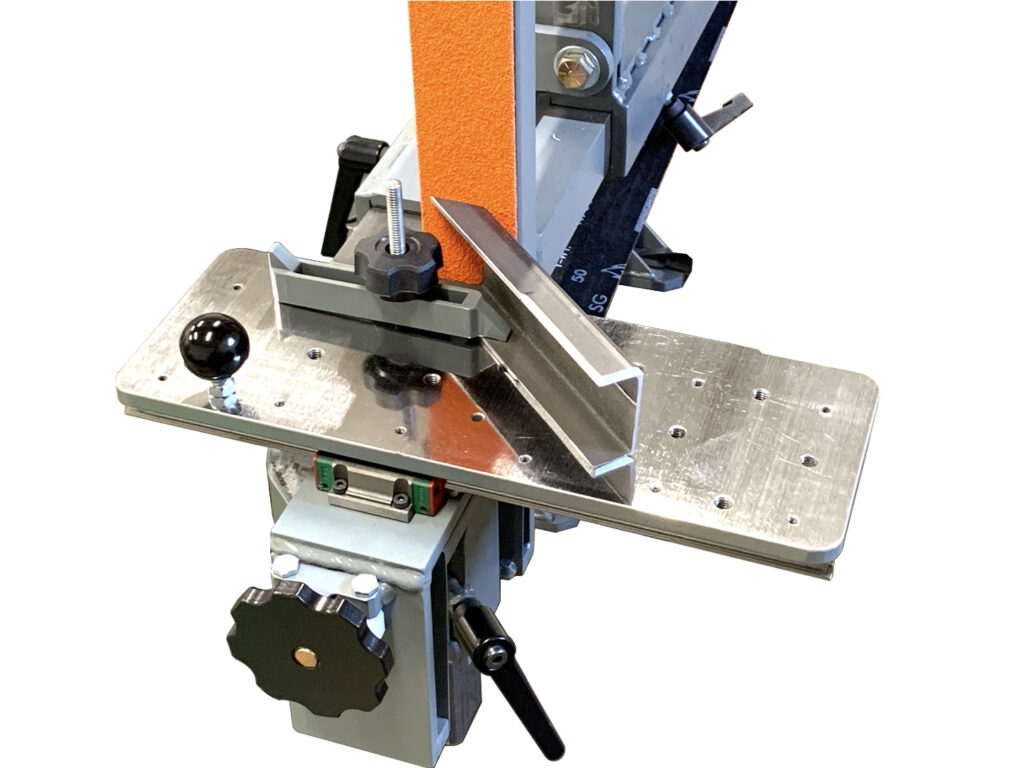

- Capable of grinding parallel faces, by using the optional Magnetic Chuck.

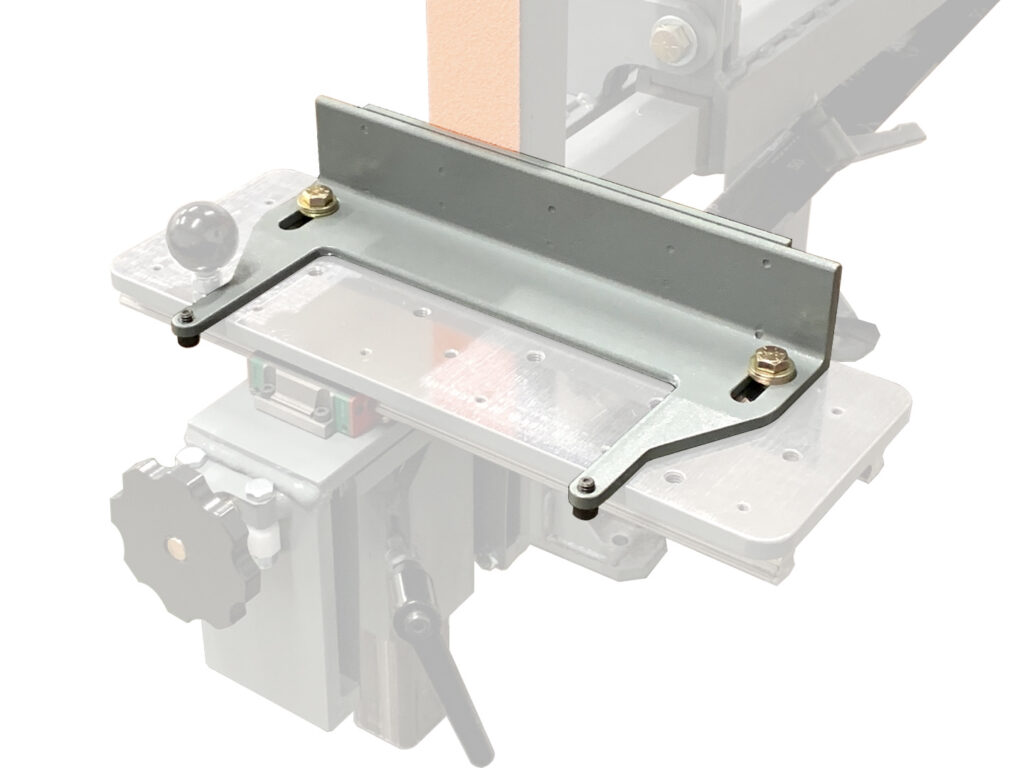

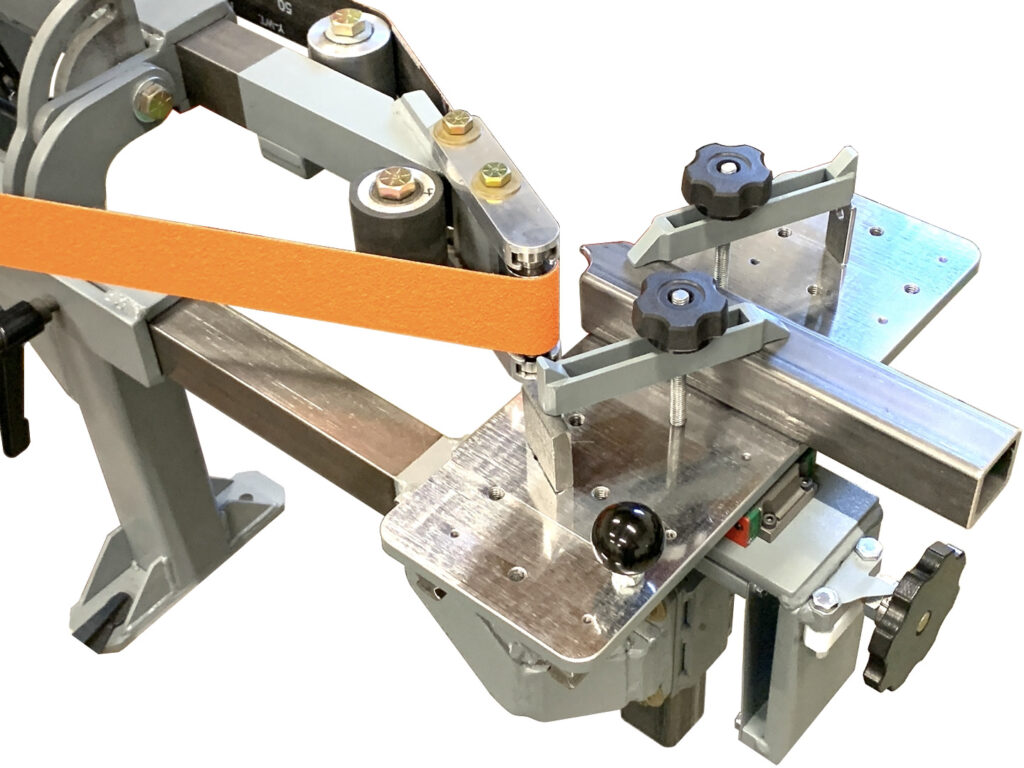

- Capable of grinding large surfaces up to 7 x 16″ (190 x 400mm), by using the Platen Attachment as a third axis.

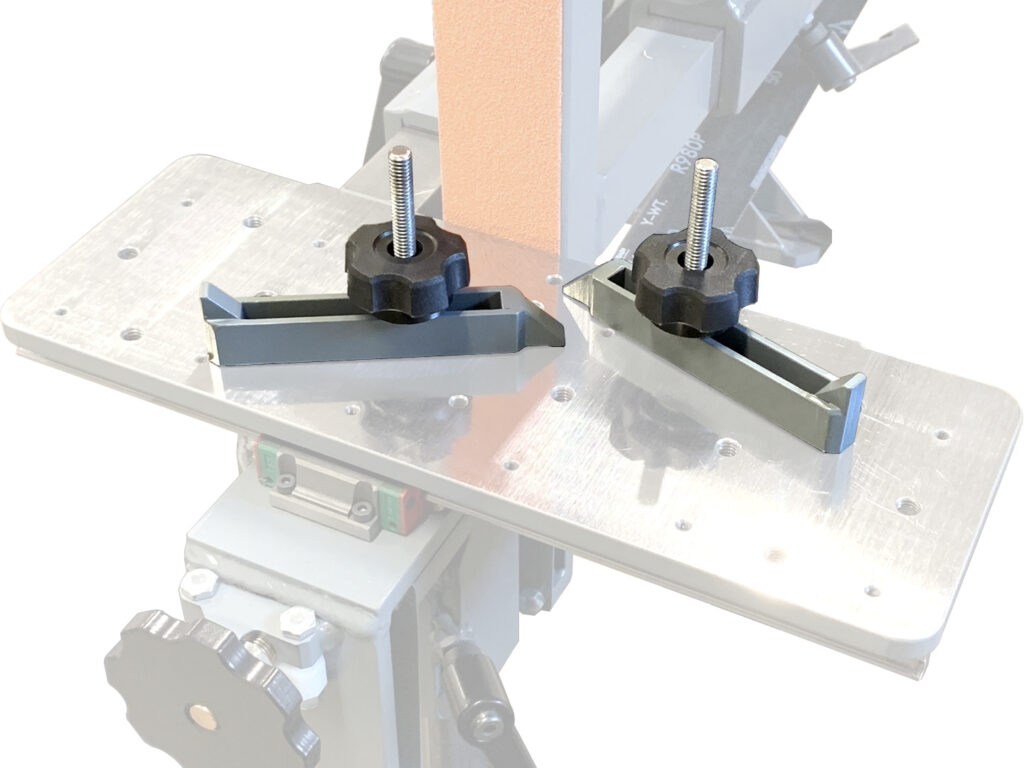

- Capable of holding very large or odd-shaped workpieces that wouldn’t fit on a traditional SGA.

- Capable of grinding very small workpieces that wouldn’t be safe to hold otherwise — just clamp them down and move the whole table.

- Capable of grinding non-ferrous workpieces, and workpieces without a flat back surface, by using the Hold-down Clamps instead of a mag chuck.

- Capable of grinding internal corners, radiuses, ledges, rabbets, flutes, hollow grinds, etc, by using the Belt Grinder’s various attachments.

- Can be made for ~$300, using only basic tools and easy-to-find parts & materials.

- Compatible with both Gen 1 & Gen 2 grinders.

- Watch the unveiling video here, watch the XY Table build video here, and watch the Mag Chuck & Hold-down Clamps video here.

- Learn more here, or purchase the plans here.