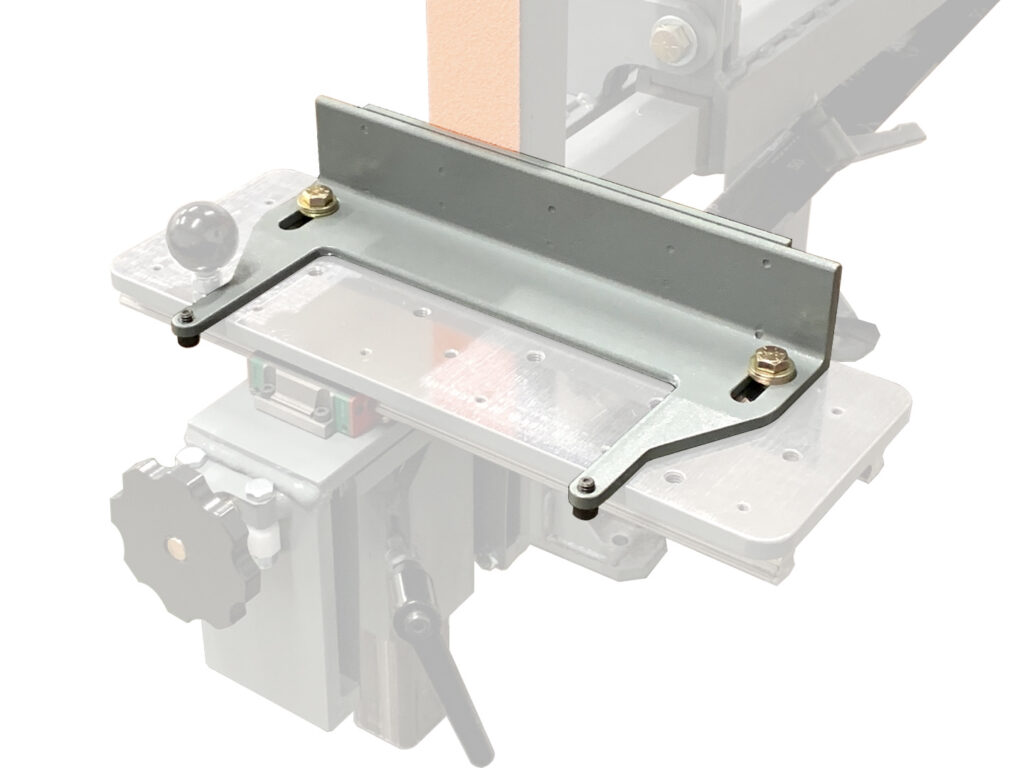

With this Magnetic Chuck mounted to the XY Table, the Belt Grinder can be used as a surface grinder. This Mag Chuck can be made from common materials, using only a drill press, the Belt Grinder itself, and some basic hand tools. It’s easier to clean than most non-switchable mag chucks, thanks to all of the irregularities being filled in with a high-temp epoxy.

Design highlights

Easy to build using basic tools & common materials

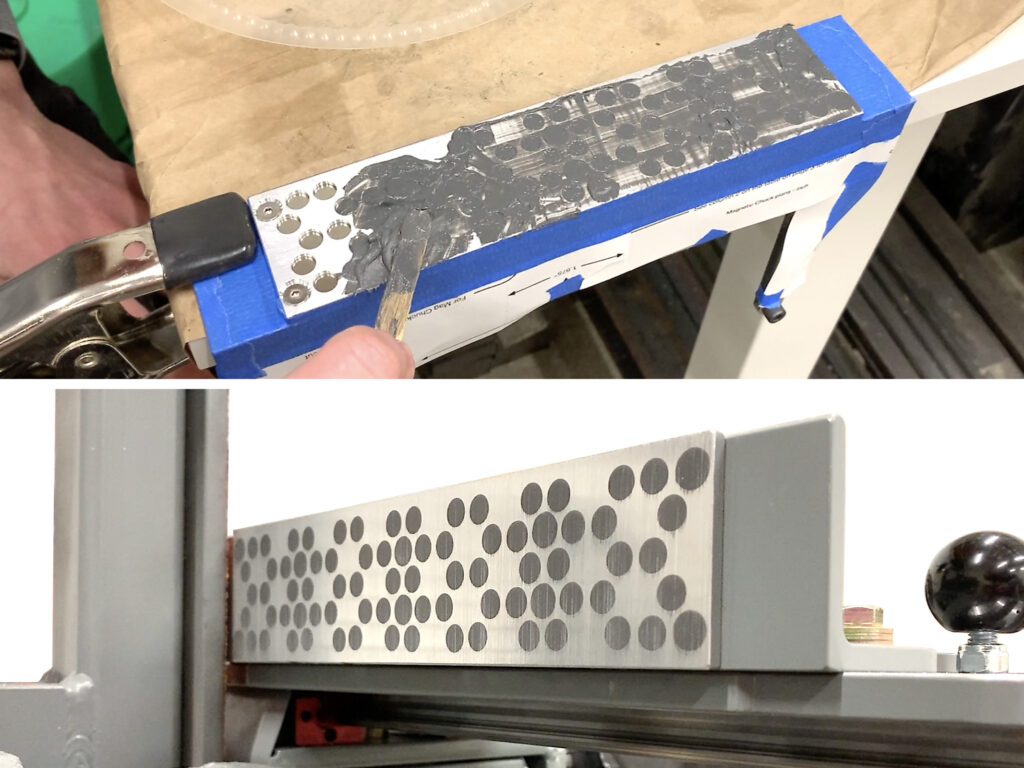

Most DIY mag chuck designs use bar magnets that need to be magnetized across their width (hard to find), and involve using a milling machine to cut grooves for those to fit in. My design uses common, axially-magnetized disk magnets, set into holes drilled in an aluminum flatbar. The holes are drilled all the way through, so the magnets can sit against a steel backer that completes the magnetic circuit and improves holding strength. The hexagonal pattern places like poles as far apart as possible, while keeping opposite poles as close together as possible, maximizing holding strength.

Epoxy potting provides a smooth surface

Always-on mag chucks are simple and cheap, but can be hard to clean, since you can’t switch them off to remove the dust. I used a high-temp epoxy (J-B Weld) to fill every crevice after assembly, so the chuck is perfectly smooth & seamless after the initial flattening. While it’s not quite as easy to clean as a switchable chuck, it is very easy to just wipe the dust off of the smooth, flat surface.

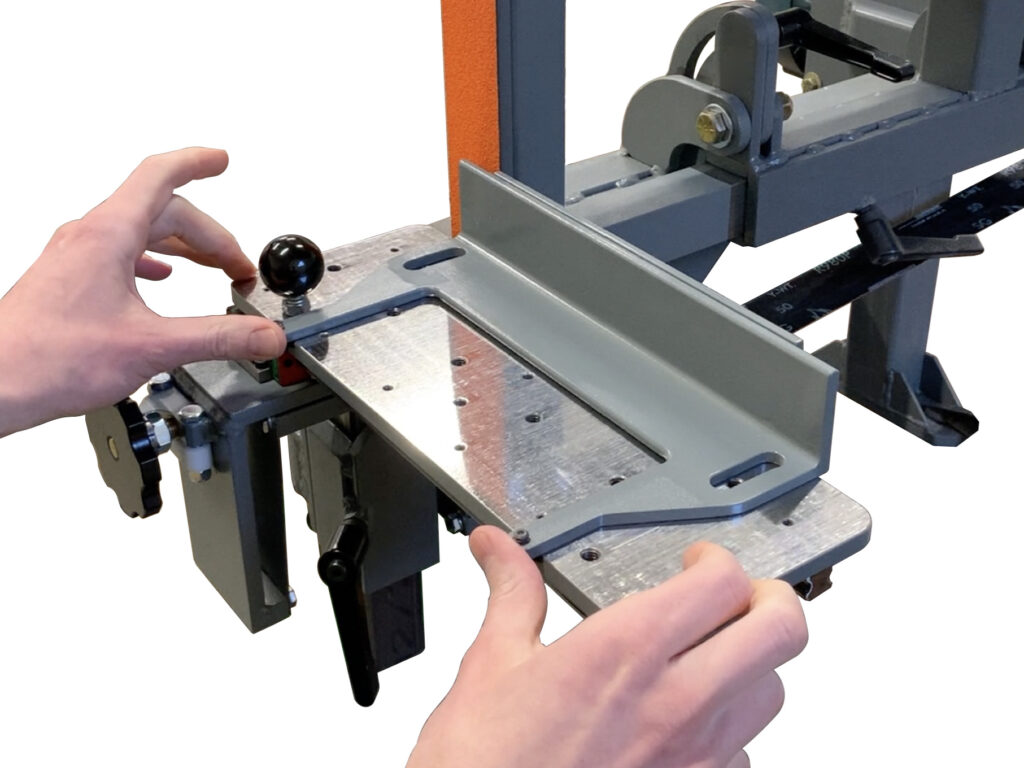

Registration pins for repeatable mounting

Since you’ll likely be taking the Mag Chuck off of the XY Table between uses (to use the XY Table for other things), it’s important that it can be re-mounted repeatably. You don’t want to have to regrind the Chuck every time! Two round pins register on the edge of the table, and you can use a spacer if needed to position it farther from the belt while keeping it parallel (this is useful if you use the Platen Attachment for surface grinding, since the table can act as a ledge that keeps small workpieces from being pulled downward). The pins can also be used to set up precise tapers of up to 5°, using gauge blocks under one of them.

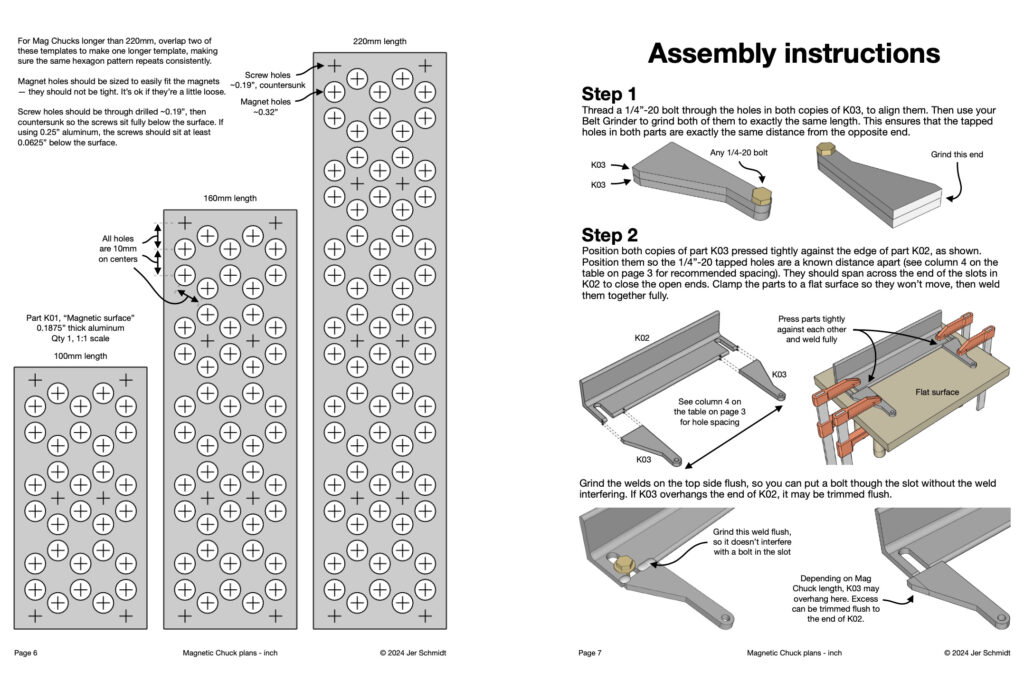

Detailed PDF plans

The plans include a list of all materials and hardware needed to complete the build, 1:1 printable templates for the parts, and detailed, step-by-step instructions with pictures to help you assemble your Mag Chuck. They also come with DXF drawings that can be used to CNC cut the parts, if desired. The plans are included with the XY Table plans, which you can buy with the buttons below.

Want one for yourself?

Like the Belt Grinder & XY Table, the Magnetic Chuck is designed to be as easy as possible to build, without compromising on performance and versatility. The only power tools required are a drill press and a welder (and the belt grinder itself), and you should be able to finish the Chuck in an afternoon. Clicking the button below will take you to Etsy to complete the transaction and download plans for the XY Table, the Hold-down Clamps, and this Mag Chuck (sold as a bundle).

If you have any questions, please see the FAQ page, or contact me.