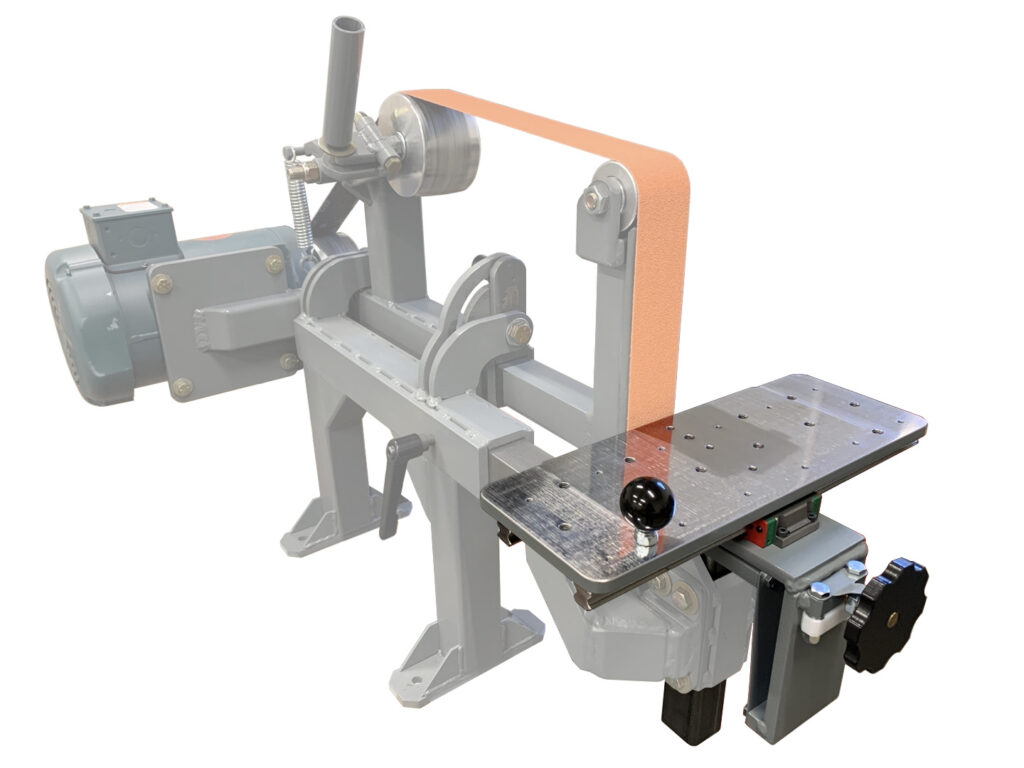

Ever since I released my original Tilting Belt Grinder design, people have been asking me for a surface grinding attachment (SGA) to work with it. It took me a really long time to design, because I find the typical SGA designs to be far too limited in functionality for how expensive & complex they are. I had to come up with something new, and that took a lot of thinking, prototyping, and iterating. But here it is! I call it the “XY Table” instead of a surface grinding attachment, because it does so much more than just surface grinding.

Design highlights

Versatile table surface

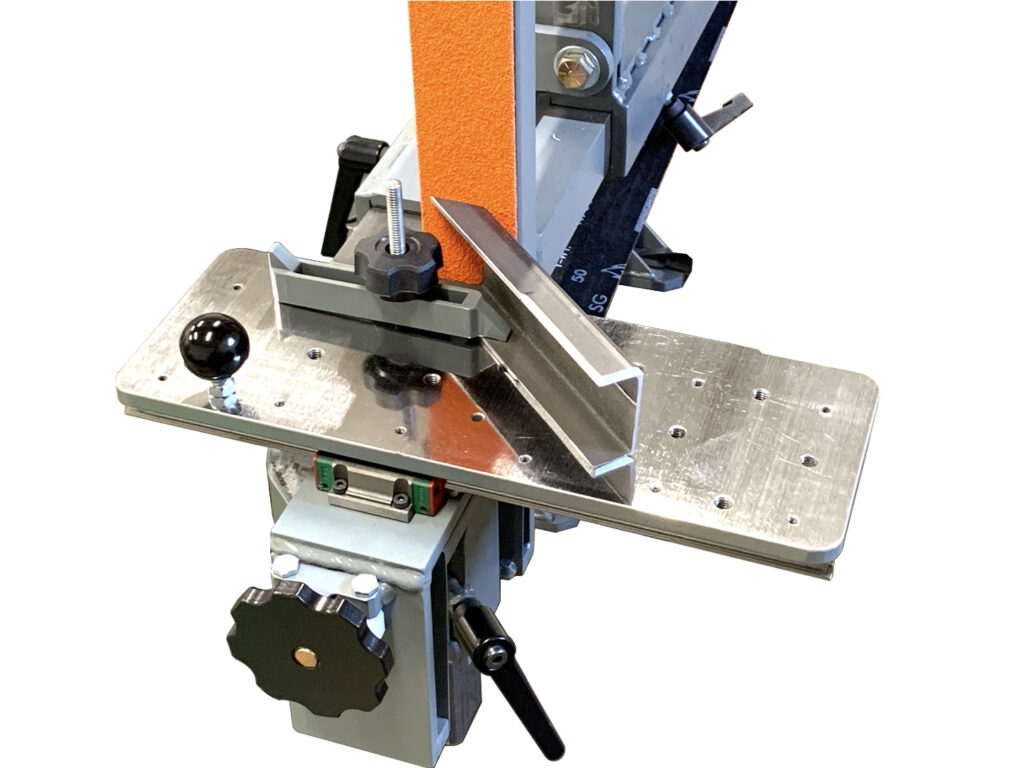

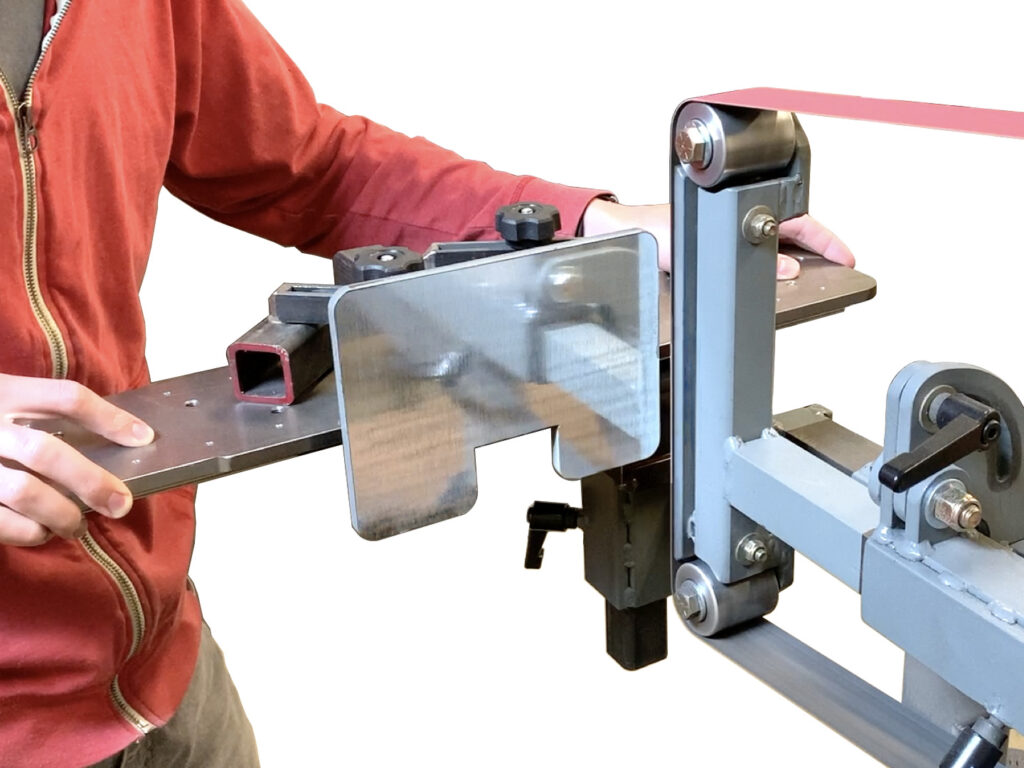

Instead of only a magnetic chuck, this XY Table has a simple, flat table surface to which you can mount anything you want. Of course you can still mount a magnetic chuck to it, so it can behave exactly like any other SGA when you need it to. But you can also clamp down tiny workpieces that wouldn’t be safe to hold otherwise, huge workpieces that don’t fit on a typical SGA, non-ferrous or odd-shaped workpieces that can’t stick to a magnet, or other jigs & fixtures.

Large grinding area

With the vertical Platen Attachment acting as a third axis, the XY Table can flatten large surfaces, up to 7 x 16″ (195 x 400mm). The workpiece shown here is 6 x 8″, less than half of the max size.

Can be used with any attachment

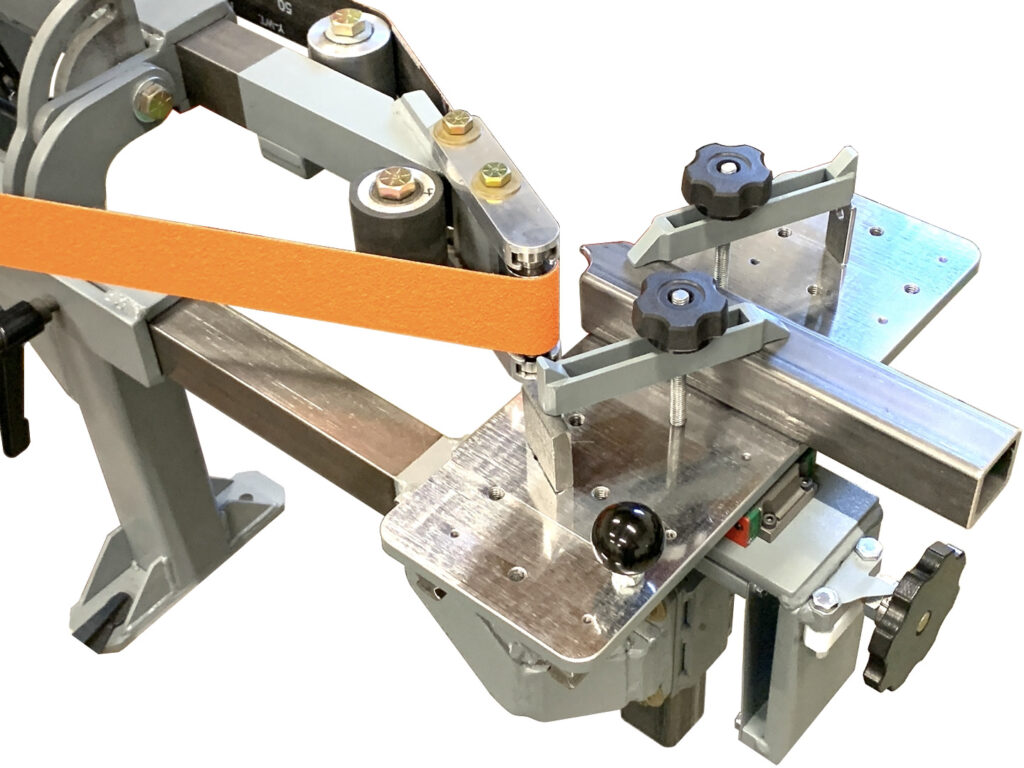

Since this is a table that goes in the belt grinder’s Table Holder, it is separate from the attachment that the belt runs around. That means it can be used with any attachment, in either orientation. It works great with the Platen Attachment in vertical mode, which enables grinding tall workpieces, and sharp internal corners. With the Small Wheel Attachment, you can grind internal radiuses and coves. With the Contact Wheel Attachment, you can grind rabbets and hollow grinds.

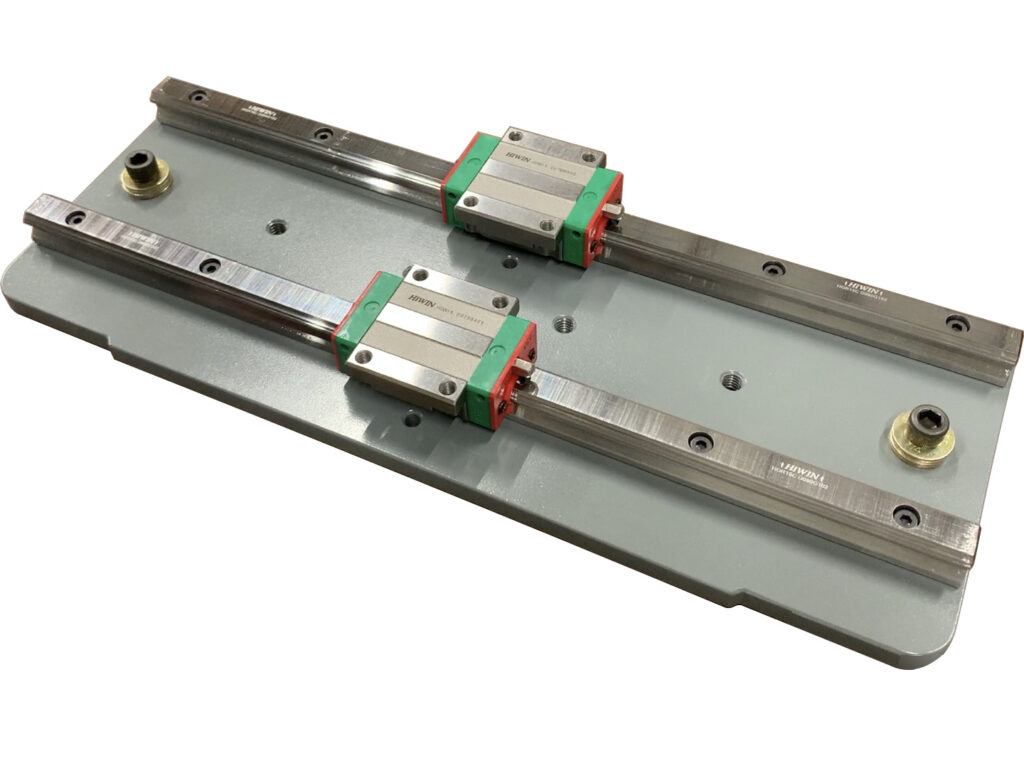

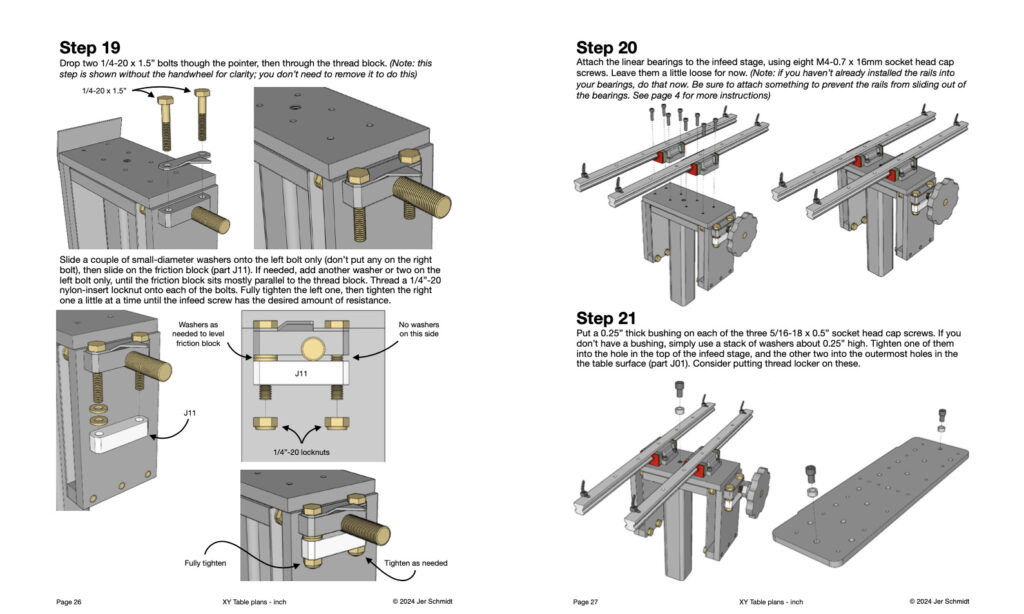

Linear bearings

Two linear ball bearings provide a smooth, precise, and strong side-to-side motion for the table. These are strong enough to support workpieces up to about 50lbs (23kg), and you can get whatever length of rails you want, to make the table as large or small as desired. This type of linear bearing is somewhat standardized across brands, so is relatively easy to source.

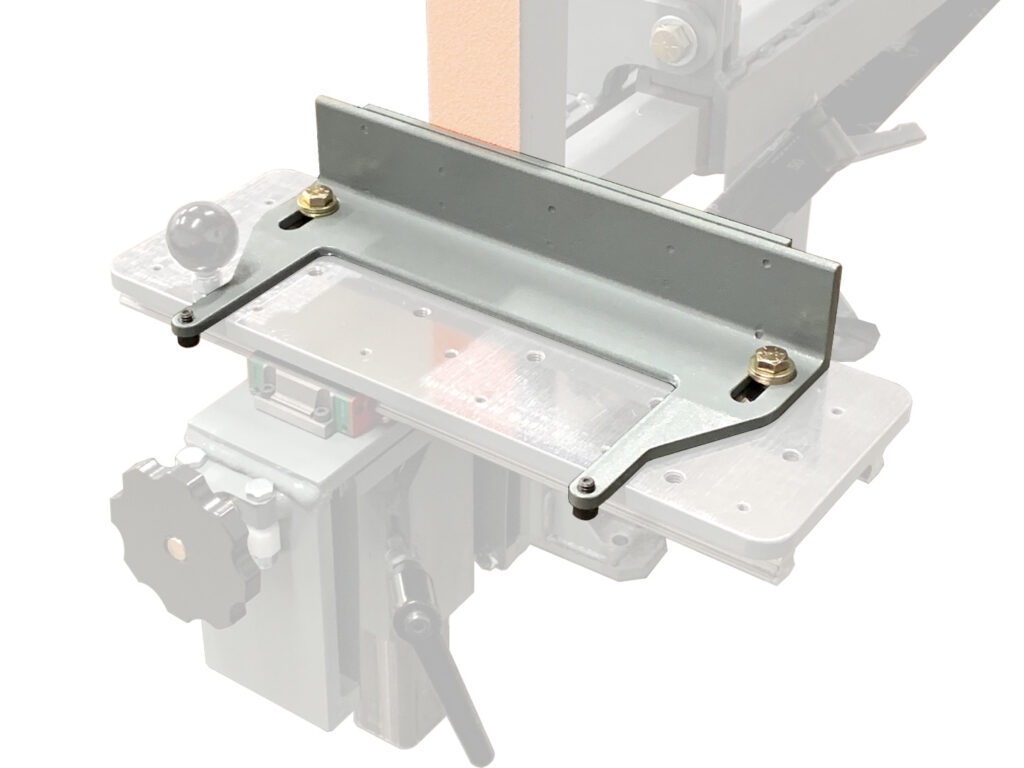

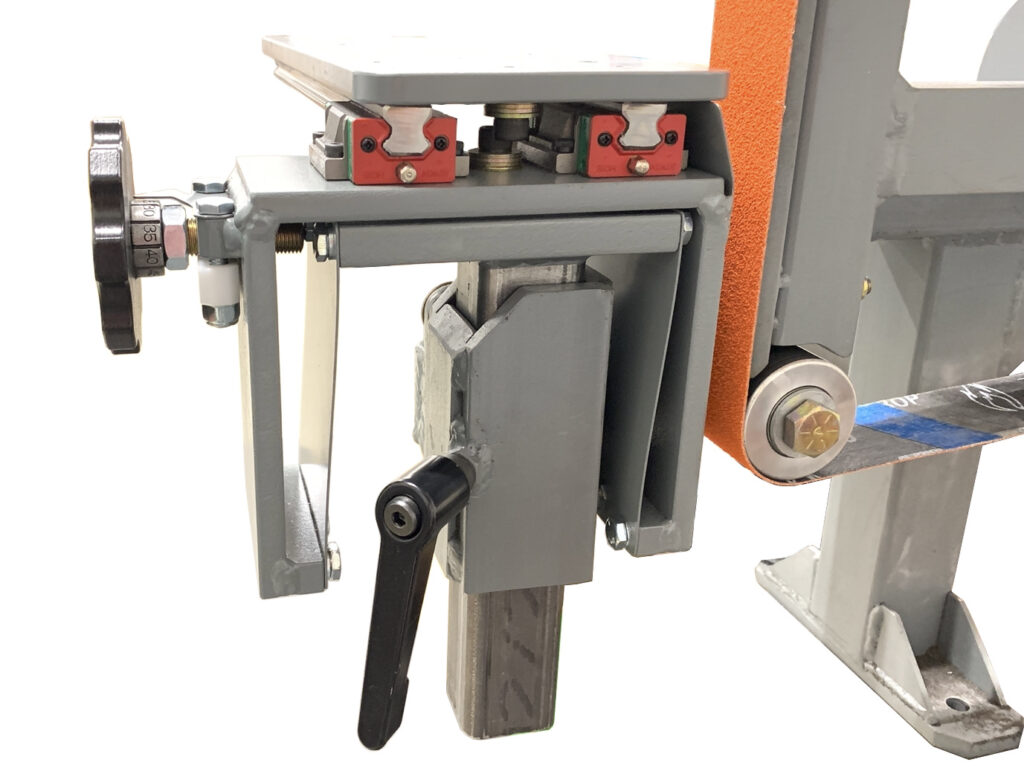

Flexures as a frictionless infeed axis

It took a lot of testing to prove to myself that flexures could actually be good enough, but they passed every test with flying colors! The two identical flexures form a parallelogram, allowing the table to move back and forth with zero backlash, zero friction, and zero stiction, all while staying perfectly flat. They’re made from common 20ga (1mm) mild steel, easy to find locally. Because of how they are supported by the rest of the frame, they’re strong enough to easily support 50+lbs on the end of the table without damage.

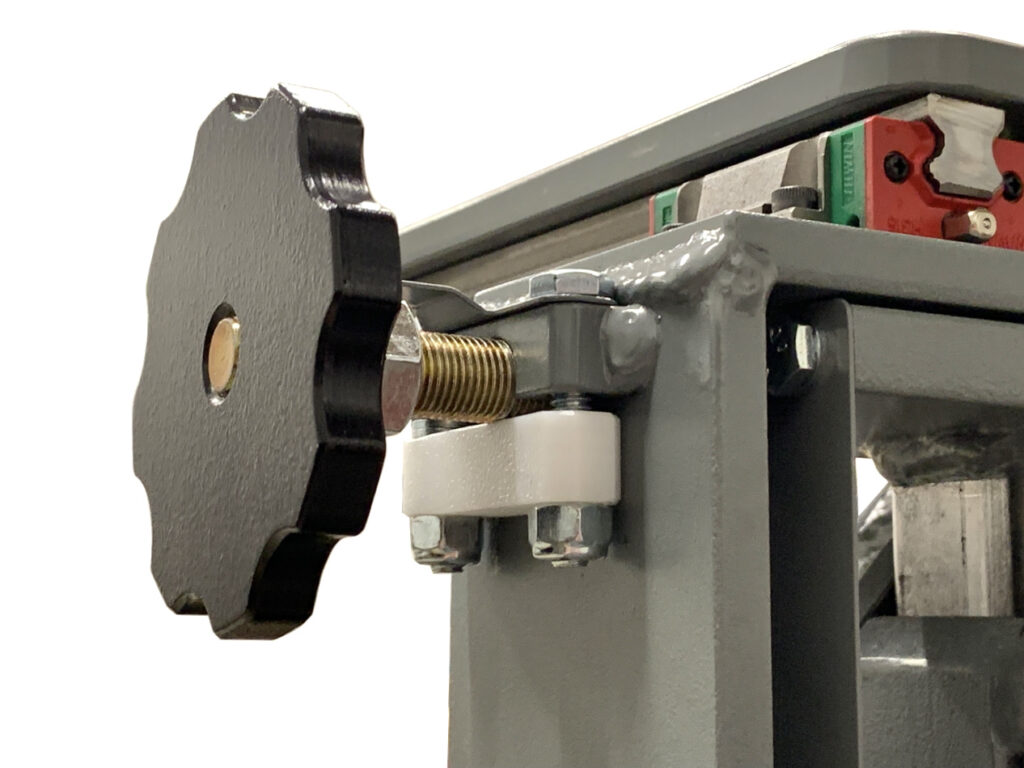

Zero-backlash infeed screw

In normal operation the table is spring-loaded toward the grinding belt, and a screw connected to the handwheel limits how far it can go toward the belt. This way there is no backlash, and you can pull the table back away from the belt without changing the stop position. A plastic block presses against the bottom of the screw to keep it straight and add a bit of friction so it doesn’t drift.

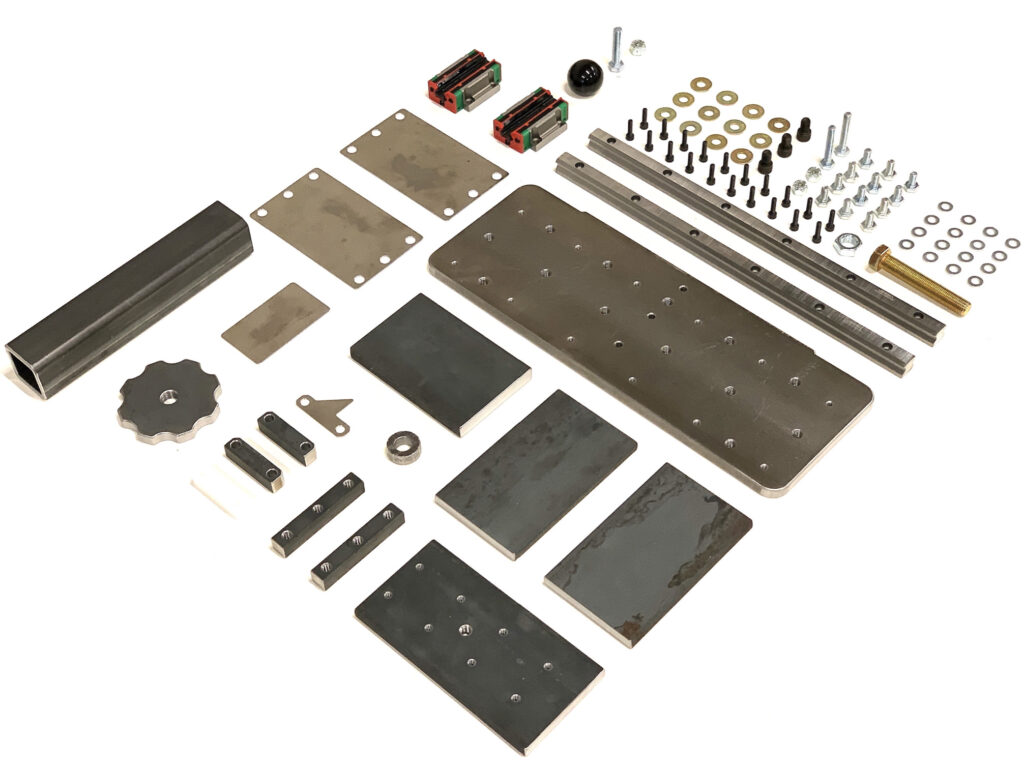

Simple, easy-to-find components

Most of the XY Table is made from common mild steel, and readily-available standard fasteners. The only special parts are the linear bearings, but I’ve chosen the most common standard for those, so they’re as easy to source as possible. You can view the shopping list here.

I designed a simple, always-on Magnetic Chuck that can be made using only a drill press. It uses a hexagon pattern of small disc magnets (which are very common and cheap), set into holes in aluminum flatbar and potted with high-temp epoxy for a smooth, easy-to-clean surface. Click here for more details. Plans for this are included with the XY Table plans.

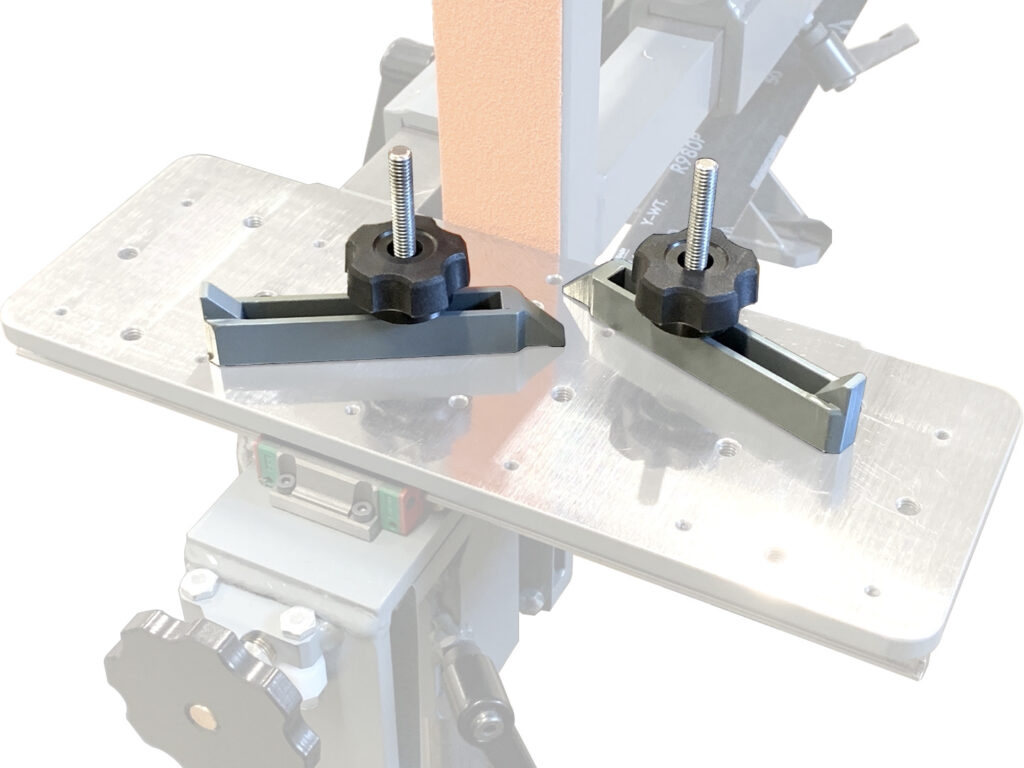

For mounting odd-shaped parts, I designed some simple Hold-down Clamps which, when mounted upside-down under the table, act as adjustable end-stops to limit (or lock) the table’s motion. Click here for more details. Plans for these are included with the XY Table plans.

Detailed PDF plans, available in inch and metric

The plans include a list of all materials and hardware needed to complete the build, 1:1 printable templates for the parts, and detailed, step-by-step instructions with pictures to help you assemble your own XY Table & accessories. They also include DXF drawings that can be used to CNC cut the parts, if desired. You can purchase and immediately download the plans with the buttons below.

Want one for yourself?

Like the Belt Grinder, the XY Table is designed to be as easy as possible to build, without compromising on performance and versatility. The only power tools required are a drill press, angle grinder, & welder, and you should be able to have your XY Table up & running in under a week. Clicking the button below will take you to Etsy to complete the transaction and download plans for this XY Table, the Magnetic Chuck, and the Hold-down Clamps (sold as a bundle).

If you have any questions, please see the FAQ page, or contact me.