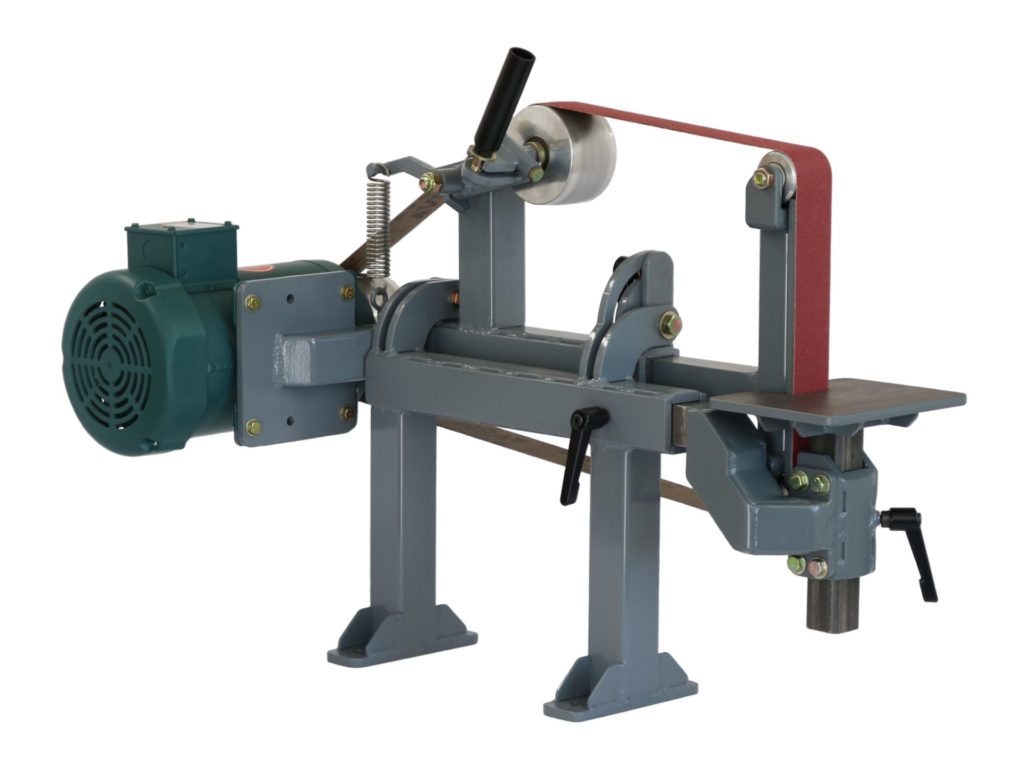

In 2017 I unveiled my design for the original Tilting Belt Grinder. It introduced several novel functions, including a central hinge that allows the machine to tilt in place, and a table holder that holds interchangeable tables on a precise two-axis slide system. The response was overwhelmingly positive, and after several years of selling plans for that original belt grinder, I’ve used the feedback from my customers to help improve my design. The Gen 2 design is simpler, and eliminates some troublesome design aspects to make it easier to build. It also introduces a metric version, designed from the ground up to use metric materials and hardware.

Design highlights

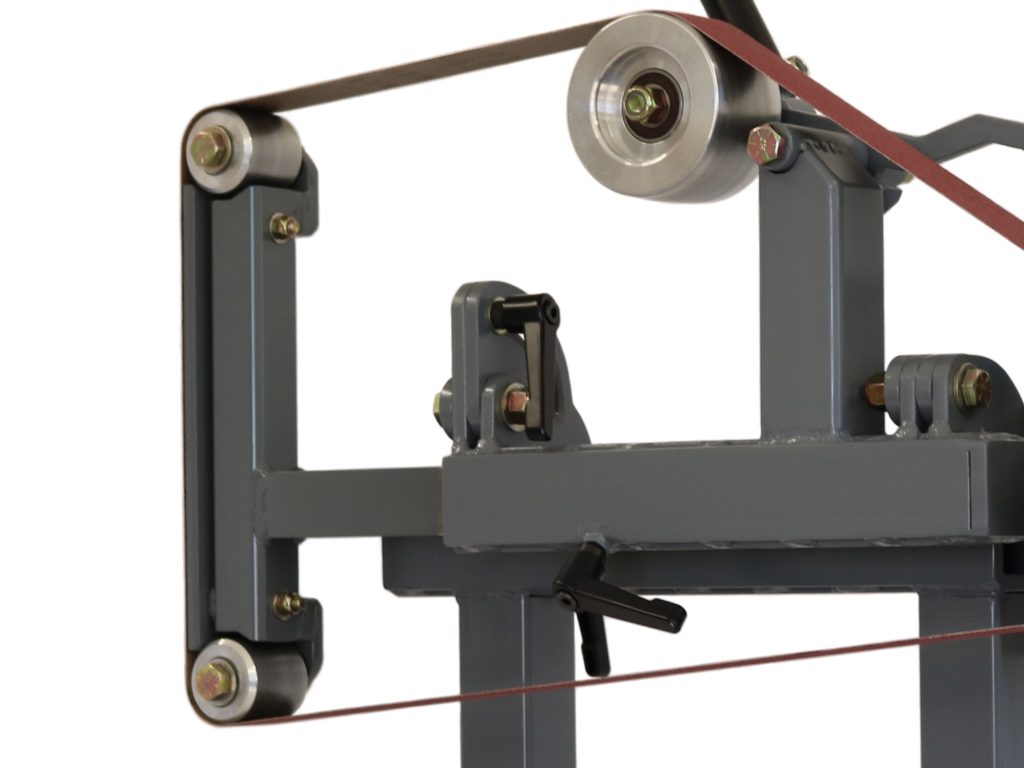

Simplified, all-new tensioner

The tensioner is now mounted on a sturdy square tube post, and uses an easy-to-find extension spring instead of a custom torsion spring. The tracking adjuster is angled forward to improve tracking responsiveness. And it’s made from fewer components so it’s easier to build.

Improved hinge geometry & tube positions

The hinge placement enables this belt grinder’s signature feature: the attachment tilts about its center point, while the table stays in place. This allows you to use the same tables for both orientations, without even repositioning it. The Gen 2 hinges enhance this by placing the tilting tube closer to the hinge, and the base tube farther from the hinge, making clearance for a wider variety of attachments. Oh and, the hinges are rounded for a more refined appearance.

The wheel mounts are easier to weld on without them warping, and the platen surface is now tunable in two directions, so it can be perpendicular to the table in either orientation. The frame is welded to the tool arm instead of bolted, so it can’t be knocked out of alignment, and it’s much, much easier to build. Learn more

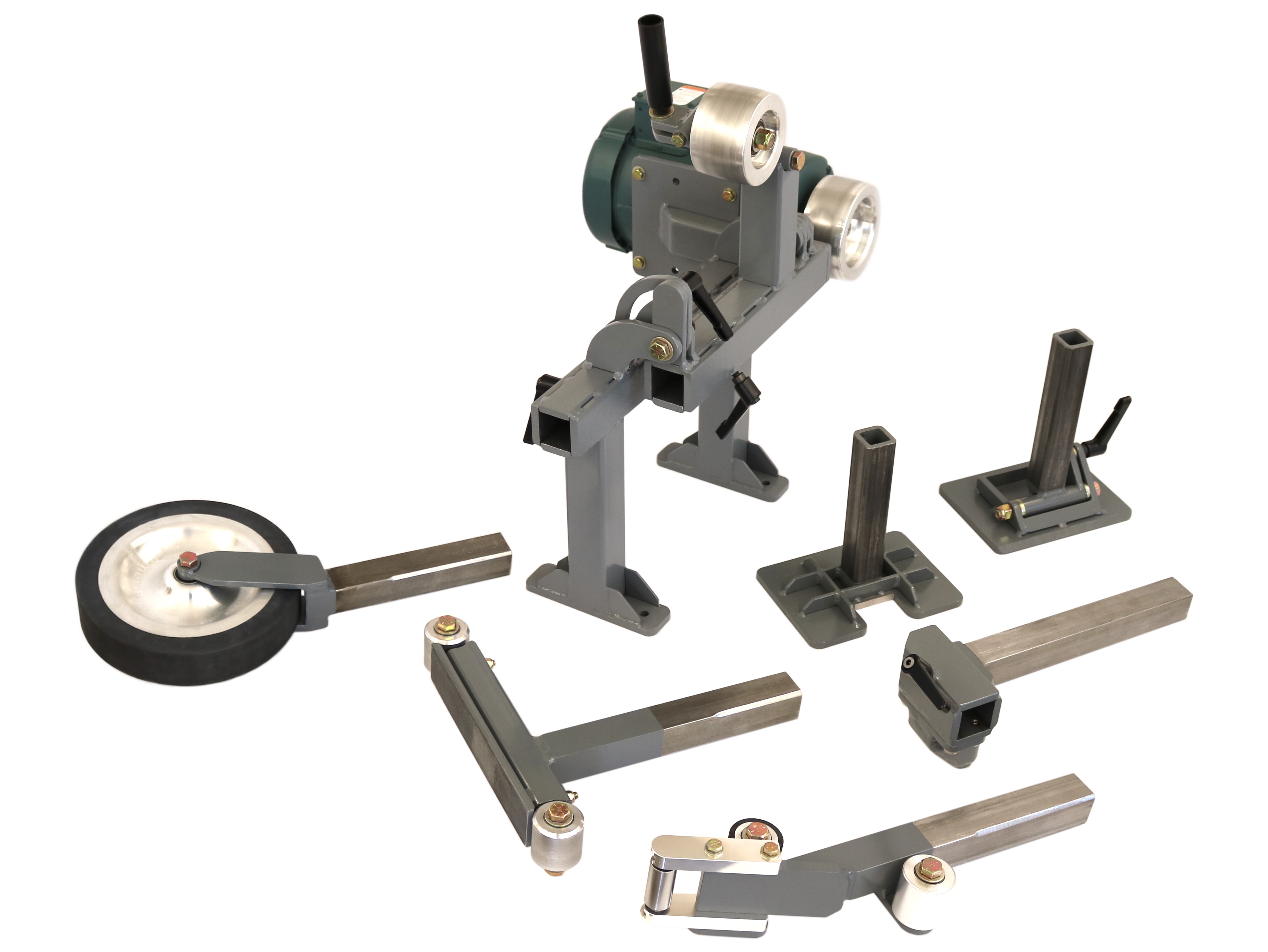

The number of custom parts was reduced from 8 to 5, and the number of welded joints from 7 to 3. The new attachment takes less than half as long to build, and costs less. The single deflector wheel can stay in place all the time – it doesn’t need to be removed when not in use. Learn more

The Contact Wheel Attachment can now accept a wider range of wheels, from 6″ up to 10″. It’s easier to swap wheels, so you can use several wheels with the same attachment. And of course, it’s easier to build. You don’t even need to drill or tap any holes. Learn more

Similar to Gen 1, the table holder slides into the base frame tube, giving you front to back adjustment. The interchangeable tables are mounted on a square tube post that slides into a vertical tube on the holder, giving you vertical adjustment (necessary when the grinder is tilted sideways). The square post also makes them indexable to four positions, and makes it easy to build new tables for specific tasks. Learn more

Outstanding versatility

With the various attachments, tables, and orientations, there are more than 50 possible combinations, so you can find the perfect configuration for the task at hand.

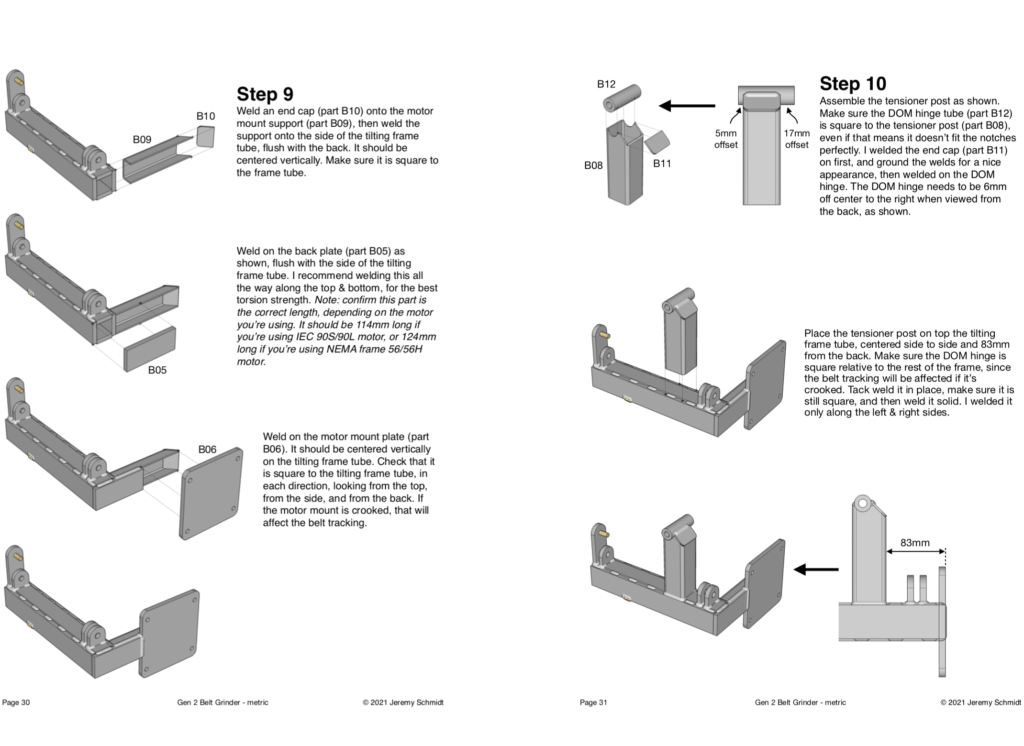

The plans include a list of all materials and hardware needed to complete the build, 1:1 printable templates for the parts, and detailed, step-by-step instructions with pictures to help you assemble your own machine. They also include DXF drawings that can be used to CNC cut the parts, if desired. You can purchase and immediately download the plans using the buttons below.

Want one for yourself?

The Gen 2 Tilting Belt Grinder is designed to be as easy as possible to build, without compromising on performance and versatility. The only power tools required are a drill press, angle grinder, & welder, and you should be able to have your grinder up & running in about a week. Clicking the button below will take you to Etsy to complete the transaction and download your plans.

If you have any questions, please see the FAQ page, or contact me.