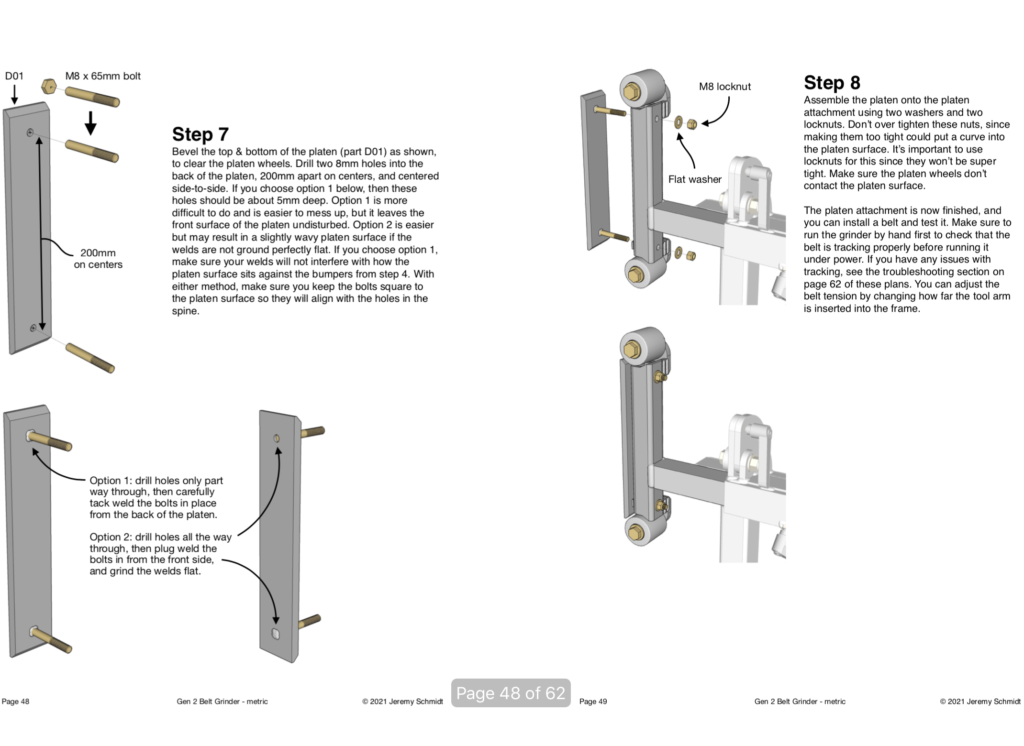

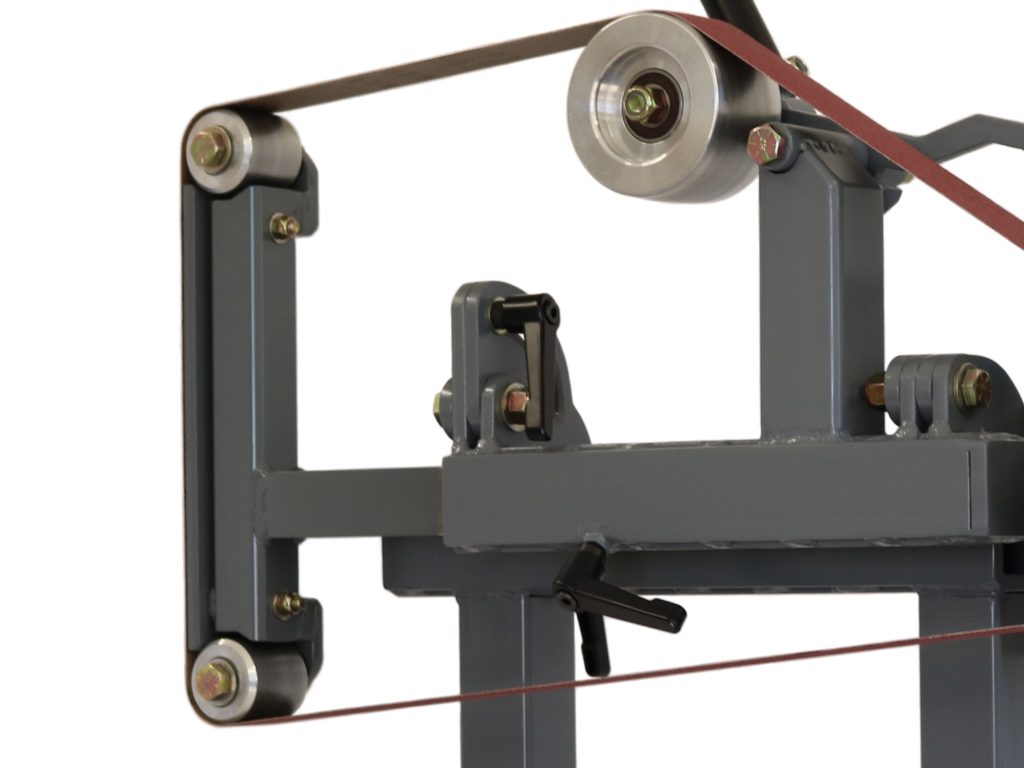

A flat platen attachment is the most common attachment for a 2×72″ belt grinder. It allows you to grind flat edges, square the end of stock, etc. Since it’s the attachment that pretty much everyone wants, I include the Platen Attachment plans with the plans for the Gen 2 Belt Grinder. This new Gen 2 Platen Attachment is improved in nearly every way compared to Gen 1. It’s made of fewer components, fewer welded joints, fewer holes (& no tapped holes), and it’s more rigid, more precise, & more user-friendly. Like all attachments for the Gen 2 Tilting Belt Grinder, this Platen Attachment is aligned with the grinder’s main hinge, so it stays centered on the table regardless of the grinder’s orientation.

Design highlights

Simpler, sleeker, and easier to build

The new platen attachment takes a fraction of the time to build, and is a lot harder to mess up. The wheel mounting ears are welded on by tightly clamping them to the frame, so they can’t warp while welding. This wasn’t possible with the Gen 1 design, so it was a troublesome step. And Gen 1 was assembled with a hard-to-make tube bolted to the tool arm, which was bulky and could get knocked out of alignment easily. On Gen 2, the frame is simply welded directly to the tool arm.

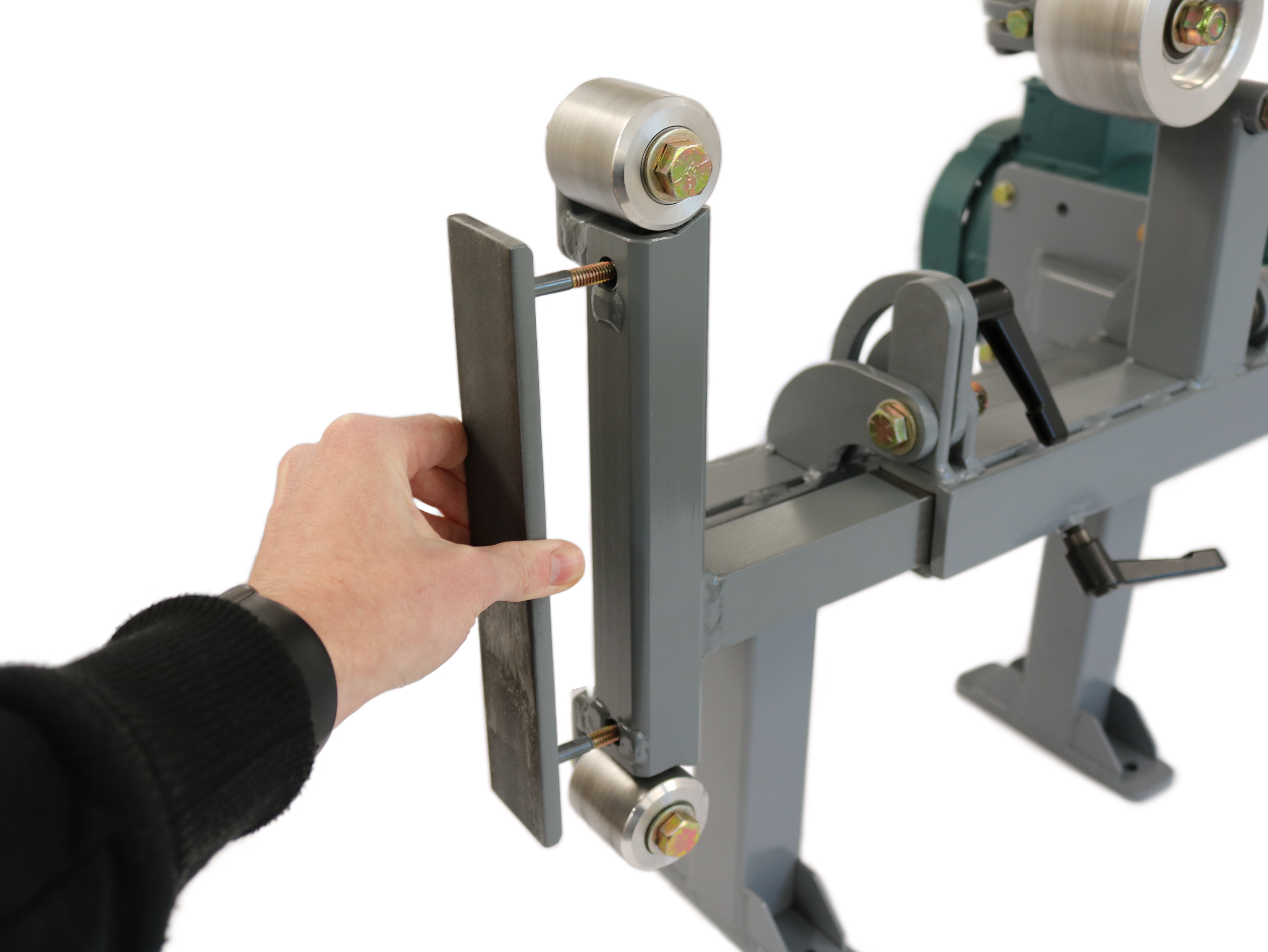

Removable platen, now tunable in two directions

You can now tune the platen surface in both directions, to ensure it is perpendicular to the table when the grinder is vertical and when it’s horizontal. The adjustment is made by filing down one or two of the three contact points that the platen surface rests against. You can easily remove the platen surface to use it as a slack belt attachment, without losing your carefully tuned squareness.

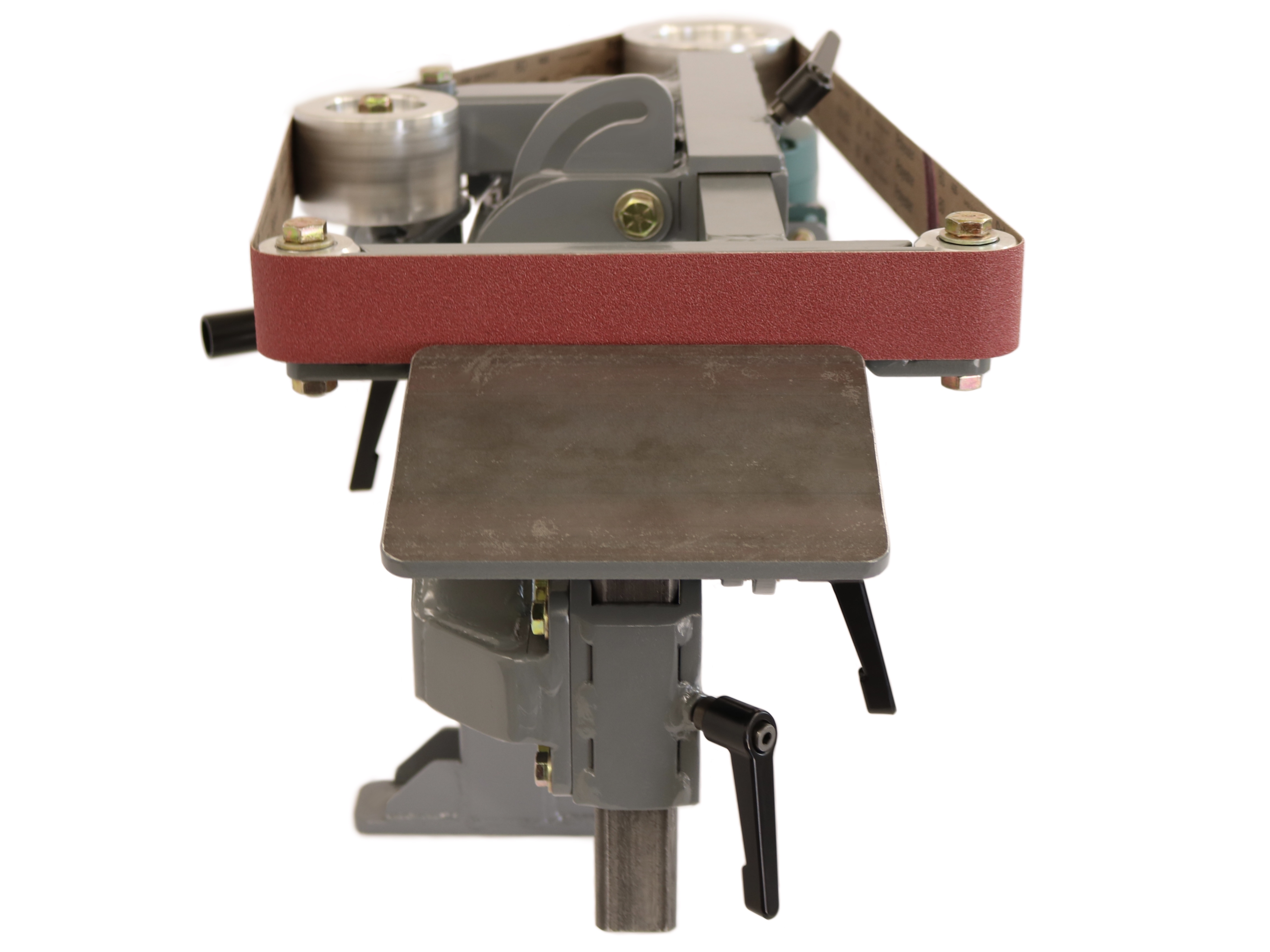

Centered on the hinge, so it tilts in place

The short legs on Gen 1 limited the position of the platen attachment, so it was not vertically centered on the hinge. This meant that when it was tilted sideways, the platen was off to the left of the table. With Gen 2 , the platen is properly centered on the table in either orientation. This also enables the table to fit under the platen attachment. The platen surface is slightly longer, so you have more working area when the grinder is tilted horizontal.

The plans for this new Platen Attachment are included with the Belt Grinder plans, which include a list of all materials and hardware needed to complete the build, 1:1 printable templates for the parts, and detailed, step-by-step instructions with pictures to help you assemble the attachment. They also include DXF drawings that can be used to CNC cut the parts, if desired. You can purchase and immediately download the plans using the buttons below.

Want one for yourself?

Like the Belt Grinder, the Platen Attachment is designed to be as easy as possible to build, without compromising on performance and versatility. The only power tools required are a drill press, angle grinder, & welder, and you should be able to finish the attachment in an afternoon. Clicking the button below will take you to Etsy to complete the transaction and download your plans.

If you have any questions, please see the FAQ page, or contact me.